We have just delivered a full container of fiber optic to our customer which is one of the biggest cable company in Morocco.

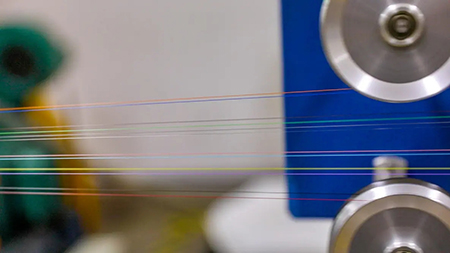

We bought the bare G652D and G657A2 fiber from YOFC which is the best fiber manufacturer in China, also famous in the world, then we colored it into twelve different colors(Red, Blue, Green, Yellow, Violet, White, Orange, Brown, Grey, Black, Pink, Aqua) and make sure there’s no joint in every plate of 50.4km.

The production quality of fiber coloring process has a direct impact on the quality and service life of fiber optic cable. In the actual production process, we often encounter quality problems such as eccentricity of coloring, light color, poor curing, large attenuation and fiber breakage after coloring.

In order to prevent the possible problems, the technical staff of ONE WORLD factory will do a comprehensive inspection of the fiber guide pulley, take-up tension, coloring ink and workshop environment before each production to control the quality of fiber coloring to the greatest extent.

At the same time, ONE WORLD’s quality inspection personnel will also test each tray of optical fiber to ensure that all the factory products are qualified and meet customer requirements.

Provide high-quality, cost-effective wire and cable materials to help customers save costs while improving product quality. Win-win cooperation has always been the purpose of our company. ONE WORLD is gladly to be a global partner in providing high performance materials for the wire and cable industry. We have a lot of experience in developing together with cable companies all over the world.

Please don’t hesitate to contact us if you want to improve your business. Your short message maybe means a lot for your business. ONE WORLD will serve you wholeheartedly.

Post time: Dec-10-2022