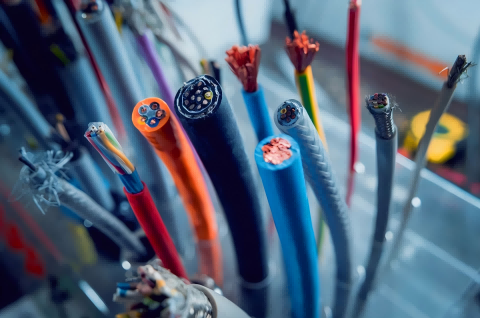

Cables are essential components of industrial wire harnesses, ensuring stable and reliable electrical signal transmission for industrial equipment. The cable jacket is a key factor in providing insulation and environmental resistance properties. As global industrialization continues to develop, industrial equipment faces increasingly complex operating environments, which raises higher demands for cable jacket materials.

Therefore, choosing the right cable jacket material is crucial, as it directly impacts the stability and lifespan of the equipment.

1. PVC (Polyvinyl Chloride) Cable

Features: PVC cables offer excellent weather resistance, chemical corrosion resistance, and good insulation properties. They are suitable for both high and low temperatures, fire-resistant, and can be softened by adjusting the hardness. They are low-cost and widely used.

Usage Environment: Suitable for indoor and outdoor environments, light machinery equipment, etc.

Notes: Not suitable for high temperatures, high oil, or high-wear environments. Poor heat resistance and dielectric constant vary with temperature. When burned, toxic gases, mainly hydrochloric acid, are released.

2. PU (Polyurethane) Cable

Features: PU cables have excellent abrasion resistance, oil resistance, and weather resistance.

Usage Environment: Suitable for industrial equipment, robotics, and automation equipment in industries such as construction machinery, petrochemicals, and aerospace.

Notes: Not suitable for high-temperature environments. Typically used in temperatures ranging from -40°C to 80°C.

3. PUR (Polyurethane Rubber) Cable

Features: PUR cables provide excellent abrasion resistance, oil resistance, ozone resistance, chemical corrosion resistance, and weather resistance.

Usage Environment: Suitable for harsh environments with high abrasion, oil exposure, ozone, and chemical corrosion. Widely used in industrial equipment, robotics, and automation.

Notes: Not suitable for high temperatures. Typically used in temperatures ranging from -40°C to 90°C.

4. TPE (Thermoplastic Elastomer) Cable

Features: TPE cables offer excellent low-temperature performance, flexibility, and aging resistance. They have good environmental performance and are halogen-free.

Usage Environment: Suitable for various factory environments, medical devices, food industry, etc.

Notes: Fire resistance is weaker, not suitable for environments with high fire safety requirements.

5. TPU (Thermoplastic Polyurethane) Cable

Features: TPU cables provide excellent abrasion resistance, oil resistance, weather resistance, and good flexibility.

Usage Environment: Suitable for engineering machinery, petrochemical, aerospace industries.

Notes: Fire resistance is weaker, not suitable for environments with high fire safety requirements. High cost, and difficult to process in stripping.

6. PE (Polyethylene) Cable

Features: PE cables offer good weather resistance, chemical corrosion resistance, and good insulation properties.

Usage Environment: Suitable for indoor and outdoor environments, light machinery equipment, etc.

Notes: Not suitable for high temperatures, high oil, or high-wear environments.

7. LSZH (Low Smoke Zero Halogen) Cable

Features: LSZH cables are made from environmentally friendly thermoplastic materials such as polyethylene (PE), polypropylene (PP), and thermoplastic polyurethane (TPU). They are halogen-free and do not release toxic gases or dense black smoke when burned, making them safer for humans and equipment. They are an eco-friendly cable material.

Usage Environment: Primarily used in places where safety is a high priority, such as public spaces, subways, tunnels, high-rise buildings, and other fire-prone areas.

Notes: Higher cost, not suitable for high temperatures, high oil, or high-wear environments.

8. AGR (Silicone) Cable

Features: Silicone cables are made from silicone materials, offering good acid resistance, alkali resistance, and antifungal properties. They can withstand high-temperature and humid environments while maintaining flexibility, high waterproof performance, and high voltage resistance.

Usage Environment: Can be used in environments ranging from -60°C to +180°C for extended periods. Widely used in power generation, metallurgy, and chemical industries.

Notes: Silicone material is not abrasion-resistant, does not resist corrosion, is not oil-resistant, and has low jacket strength. Avoid sharp and metallic surfaces, and it is recommended to install them securely.

Post time: Feb-19-2025