Wires and cables are an integral part of the power system and are used to transmit electrical energy and signals. Depending on the use environment and application scenario, there are many types of wire and cable. There are bare copper wires, power cables, overhead insulated cables, control cables, cloth wires and special cables and so on.

In addition to the above common wire and cable types, there are some special wire and cable, such as high temperature wire and cable, corrosion resistant wire and cable, wear-resistant wire and cable. These wires and cables have special properties and uses, suitable for specific application scenarios and industries.

In short, according to different use environments and application scenarios, choosing the right type of wire and cable can ensure the safe and stable operation of the power system. At the same time, the quality and safety performance of wire and cable is also directly related to the safety of personal property, so pay attention to the selection of regular brands and reliable quality wire and cable in the process of use. The following describes several common wire and cable types and their characteristics. Hope to help you better understand the meaning of the specification model.

The first type of wire and cable: bare copper wire

Bare wire and bare conductor products refer to conductive wire without insulation and sheath, mainly including bare single wire, bare stranded wire and profile three series of products.

Copper aluminum single wire: including soft copper single wire, hard copper single wire, soft aluminum single wire, hard aluminum single wire. Mainly used as a variety of wire and cable semi-products, a small amount of communication wire and motor appliances manufacturing.

Bare stranded wire: including hard copper stranded wire (TJ), hard aluminum stranded wire (LJ), aluminum alloy stranded wire (LHAJ), steel core aluminum stranded wire (LGJ) is mainly used for the connection of electrical equipment and electronic appliances or components, the specifications of the above various stranded wires range from 1.0-300mm².

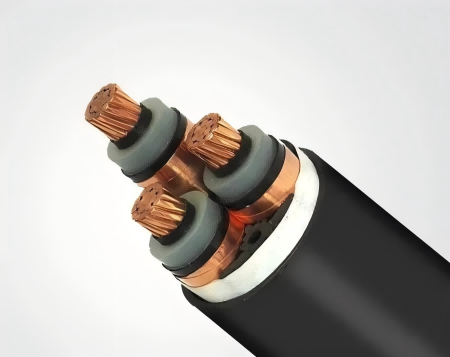

The second type of wire and cable: power cable

Power cable in the backbone of the power system for the transmission and distribution of high-power power cable products, including 1 ~ 330KV and above various voltage levels, various insulation power cables.

The section is 1.5, 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400, 500, 630, 800mm², and the core number is 1, 2, 3, 4, 5, 3+1, 3+2.

Power cables are divided into low voltage cables, medium voltage cables, high voltage cables and so on. According to the insulation conditions are divided into plastic insulated cables, rubber insulated cables, mineral insulated cables and so on.

The third type of wire and cable: overhead insulated cable

Overhead cable is also very common, it is characterized by no jacket. Many people have three misconceptions about these cables. First, its conductors are not only aluminum, but also copper conductors (JKYJ, JKV) and aluminum alloys (JKLHYJ). Now there are also steel core aluminum stranded overhead cables (JKLGY). Second, it is not only single core, the common is generally single core, but it can also be composed of several conductors. Third, the voltage level of the overhead cable is 35KV and below, not only 1KV and 10KV.

The fourth type of wire and cable: control cable

This kind of cable structure and power cable is similar, is characterized by only copper core, no aluminum core cable, conductor cross-section is small, the number of cores is more, such as 24*1.5, 30*2.5 etc.

Suitable for AC rated voltage 450/750V and below, power stations, substations, mines, petrochemical enterprises and other stand-alone control or unit equipment control. In order to improve the ability of control signal cable to prevent internal and external interference, shielding layer is mainly adopted.

Common models are KVV, KYJV, KYJV22, KVV22, KVVP. Model meaning: “K” control cable class, “V” PVC insulation, “YJ” crosslinked polyethylene insulation, “V” PVC sheath, “P” copper wire shield.

For the shielding layer, the common KVVP is a copper wire shield, if it is a copper strip shield, it is expressed as KVVP2, if it is an aluminum-plastic composite tape shield, it is KVVP3.

The fifth kind of wire and cable: House Wiring Cable

Mainly used in household and distribution cabinets, and the often said BV wire belongs to cloth wires. Models are BV, BLV, BVR, RVV, RVVP, BVVB and so on.

In the model representation of wire and cable, B is often seen, and different places represent different meanings.

For example, BVVB, the beginning of the B is the meaning of wire, it is to indicate the application classification of the cable, just like JK means overhead cable, K means control cable. The B at the end represents the flat type, which is an additional special requirement for the cable. The meaning of BVVB is: copper core polyvinyl chloride insulated polyvinyl chloride sheathed flat cable.

The sixth type of wire and cable: Special cable

Special cables are cables with special functions, mainly including flame retardant cables (ZR), low smoke halogen-free cables (WDZ), fire-resistant cables (NH), explosion-proof cables (FB), rat-proof cables and termite-proof cables (FS), water-resistant cables (ZS), etc. Flame retardant cable (ZR), low smoke halogen-free cable (WDZ) : mainly suitable for important power and control systems.

When the line encounters a fire, the cable can only burn under the action of the external flame, the amount of smoke is small, and the harmful gas (halogen) in the smoke is also very small.

When the external flame disappears, the cable can also extinguish itself, so that the fire to the human body and property damage is reduced to a minimum. Therefore, this kind of cable is widely used in petrochemical, electric power, metallurgy, high-rise buildings and densely populated and other important places.

Refractory cable (NH) : mainly suitable for particularly important power and control systems. When the line is in case of fire, the fire-resistant cable can resist the high temperature of 750~800 ° C for more than 90 minutes to ensure safe power transmission to win sufficient fire fighting and disaster reduction time.

In the face of special occasions, new products are constantly derived, such as fire-resistant cables, fire-retardant cables, low-smoke halogen free/low-smoke low-halogen cables, termite-proof/rat-proof cables, oil/cold/temperature/wear-resistant cables, radiation cross-linked cables, etc.

Post time: Nov-20-2024