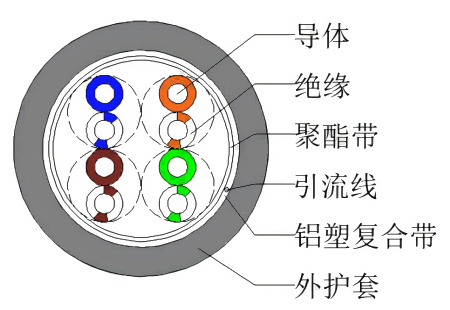

When the cable system is laid underground, in an underground passage or in water that is prone to water accumulation, in order to prevent water vapor and water from entering the cable insulation layer and ensure the service life of the cable, the cable should adopt a radial impervious barrier layer structure, which includes a metal sheath and a metal-plastic composite sheath. Lead, copper, aluminum and other metal materials are commonly used as metal sheaths for cables; A metal-plastic composite tape and a polyethylene sheath form a metal-plastic composite sheath of a cable. Metal-plastic composite sheathing, also known as comprehensive sheathing, is characterized by softness, portability, and water permeability is much smaller than plastic, rubber sheathing, suitable for places with high waterproof performance requirements, but compared with metal sheathing, metal-plastic composite sheathing still has a certain permeability.

In the European medium voltage cable standards such as HD 620 S2: 2009, NF C33-226: 2016, UNE 211620: 2020, single-side coated plastic coated aluminum tape is used as a comprehensive waterproof cover for power cables. The metal layer of single-sided plastic coated aluminum tape is in direct contact with the insulating shield, and plays the role of metal shield at the same time. In the European standard, it is necessary to test the stripping force between the plastic coated aluminum tape and the cable sheath and carry out corrosion resistance tests to measure the radial water resistance of the cable; At the same time, it is also necessary to measure the DC resistance of the plastic coated aluminum tape to measure its ability to carry short circuit current.

1. Classification of plastic coated aluminum tape

According to the different number of plastic film coated with aluminum substrate material, it can be divided into two kinds of longitudinal coating process: double-sided plastic coated aluminum tape and single-sided plastic coated aluminum tape.

The comprehensive waterproof and moisture-proof protective layer of medium and low voltage power cables and optical cables composed of double-sided plastic coated aluminum tape and polyethylene, polyolefin and other sheathing plays the role of radial water and moisture-proof. Single-sided plastic coated aluminum tape is mostly used for metal shielding of communication cables.

In some European standards, in addition to being used as a comprehensive waterproof sheath, single-sided plastic coated aluminum tape is also used as a metal shield for medium voltage cables, and aluminum tape shielding has obvious cost advantages compared with copper shielding.

2. Longitudinal wrapping process of plastic coated aluminum tape

The longitudinal wrapping process of the aluminum-plastic composite strip refers to the process of transforming the plastic coated aluminum tape from the original flat shape to the tube shape through a series of mold deformation, and bonding the two edges of the plastic coated aluminum tape. The two edges of the plastic coated aluminum tape are flat and smooth, the edges are bonded tightly, and there is no aluminum-plastic peeling.

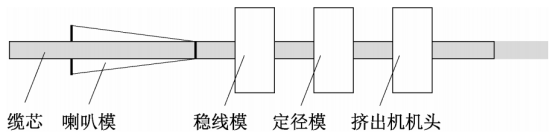

The process of changing the plastic coated aluminum tape from flat shape to tubular shape can be realized by using a longitudinal wrapping die composed of a longitudinal wrapping horn die, a line stabilizing die and a sizing die. The flow diagram of the longitudinal wrapping molding die of the plastic coated aluminum tape is shown in the following figure. The two edges of the tubular plastic coated aluminum tape can be bonded by two processes: hot bonding and cold bonding.

(1) Hot bonding process

The thermal bonding process is to use the plastic layer of the plastic coated aluminum tape to soften at 70~90℃. In the deformation process of the plastic coated aluminum tape, the plastic layer at the joint of the plastic coated aluminum tape is heated using a hot air gun or blowtorch flame, and the two edges of the plastic coated aluminum tape are bonded together using the viscosity after the softening of the plastic layer. Paste the two edges of the plastic coated aluminum tape firmly.

(2) Cold bonding process

The cold bonding process is divided into two kinds, one is to add a long stable die in the middle of the caliper die and the extruder head, so that the plastic coated aluminum tape maintains a relatively stable tubular structure before entering the head of the extruder, the exit of the stable die is close to the exit of the extruder’s die core, and the aluminum-plastic composite immediately enters the extruder’s die core after taking out the stable die. The extrusion pressure of the sheath material keeps the tubular structure of the plastic coated aluminum tape, and the high temperature of the extruded plastic softs the plastic layer of the plastic coated aluminum tape to complete the bonding work. This technology is suitable for double-sided laminated plastic coated aluminum tape, the production equipment is simple to operate, but the mold processing is relatively complex, and the plastic coated aluminum tape is easy to rebound.

Another cold bonding process is the use of hot melt adhesive bonding, hot melt adhesive melted by the extrusion machine in the longitudinal wrap horn mold position squeezed on one side of the outer edge of the plastic coated aluminum tape, the two edge positions of the plastic coated aluminum tape through the stable line and sizing die after the hot melt adhesive bonding. This technology is suitable for both double-sided plastic coated aluminum tape and single-sided plastic coated aluminum tape. Its mold processing and production equipment are simple to operate, but its bonding effect is greatly affected by the quality of hot melt adhesive.

In order to ensure the reliability of the operation of the cable system, the metal shield must be electrically connected with the insulation shield of the cable, so the single-sided plastic coated aluminum tape must be used as the metal shield of the cable. For example, the hot bonding process mentioned in this paper is only suitable for double-sided plastic coated aluminum tape, while the cold bonding process using hot melt adhesive is more suitable for single-sided plastic coated aluminum tape.

Post time: Jul-30-2024