Flame Retardant Cables

Flame-retardant cables are specially designed cables with materials and construction optimized to resist the spread of flames in the event of a fire. These cables inhibit the flame from propagating along the cable length and reduce the emission of smoke and toxic gases in the event of a fire. They are commonly used in environments where fire safety is crucial, such as public buildings, transportation systems, and industrial facilities.

Types of Materials Involved in Fire Retardant Cables

The outer and inner polymer layers are critical in fire-retardant tests, but the cable’s design remains the most significant factor. A well-engineered cable, utilizing suitable flame-retardant materials, can effectively achieve the desired fire performance properties.

Commonly used polymers for flame-retardant applications include PVC and LSZH. Both are specially formulated with flame-retardant additives to meet fire safety requirements.

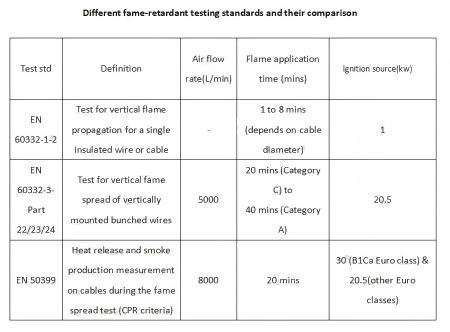

Important Tests for Flame Retardant Material and Cable Development

Limiting Oxygen Index (LOI): This test measures the minimum oxygen concentration in a mixture of oxygen and nitrogen that will support the combustion of materials, expressed as a percentage. Materials with an LOI lower than 21% are classified as combustible, while those with an LOI greater than 21% are classified as self-extinguishing. This test provides a quick and basic understanding of flammability. The applicable standards are ASTMD 2863 or ISO 4589

Cone Calorimeter: This device is used to predict real-time fire behavior and can determine parameters such as ignition time, heat release rate, mass loss, smoke release, and other properties relevant to fire characteristics. The main applicable standards are ASTM E1354 and ISO 5660, Cone calorimeter provides more reliable results.

Acid gas emission test (IEC 60754-1). This test measures the halogen acid gas content in cables, determining the amount of halogen emitted during combustion.

Gas Corrositvity test (IEC 60754-2). This test measures the pH and conductivity of corrosive materials

Smoke density test or 3m3 test (IEC 61034-2). This test measures the density of smoke produced by cables burning under defined conditions. The test is conducted in a chamber with dimensions of 3 meters by 3 meters by 3 meters (hence the name 3m³ test) and involves monitoring the reduction in light transmittance through the smoke generated during the combustion

Smoke density rating (SDR) (ASTMD 2843). This test measures the density of smoke produced by the burning or decomposition of plastics under controlled conditions . Test sample dimensions 25 mm x 25 mm x 6 mm

Post time: Jan-23-2025