Galvanized steel strand wire usually refers to the core wire or strength member of messenger wire (guy wire).

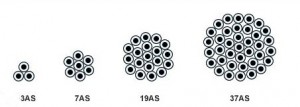

A. The steel strand is divided into four kinds according to the section structure.

Shown as the figure below structure

B. GB steel strand is divided into five grades according to nominal tensile strength: 1270MPa, 1370MPa, 1470MPa, 1570MPa, 1670MPa.

C. With the different thickness of zinc layer in galvanized steel strand, the zinc layer of steel wire in GB steel strand is divided into three levels: A, B and C.

1. Application of steel strand

The coating includes galvanized, aluminum plated, coated with nylon or plastic, etc. Galvanized steel strand wire is divided into the first thin coating and galvanized steel wire after drawing the thick coating, the mechanical properties of the thick coating is lower than the smooth wire rope, should be used in a serious corrosive environment.

2. For the stranded wire process requirements

1. The steel wire in the strand (Including the central steel wire) shall be of the same diameter, the same strength and the same zinc layer level.

2. The diameter and lay of the steel strand should be uniform and not loose after cutting.

3. The steel wire in the strand should be tightly stranded, no interleaving, fracture and bending.

The steel strand should be straight, soft, small residual stress, and should not appear ∽ shape after expansion.

5.1X3 structure steel strand wire and overhead ground wire are not allowed to join, other types of steel strand wire joints should be welded to the joint, any two joints should not be less than 50m, joint should be anticorrosion treatment.

3. Breaking tension of steel strand

There are two methods for measuring the breaking tension of steel strand

Method 1: To measure the breaking force of the whole steel strand.

Method 2: To determine the total breaking tension of steel strand?

According to the following formula:

The sum of the breaking tension of the steel wire in the strand = the minimum breaking tension of the strand X conversion coefficient

Conversion factor?

The 1X3 structure is 1.08

The 1X7 structure is 1.08

The 1X19 structure is 1.11

The 1X37 structure is 1.17

4. The surface quality

1. The surface of the steel wire in the strand should not be imprinted, scratched, broken, flattened and hard bending defects.

2. The surface of the strand must be free of oil, pollution, water and other impurities.

3. Strand split steel wire surface of the galvanized layer should be uniform and continuous, no crack and peeling phenomenon. However, the surface of zinc layer is allowed to have a small amount of flash and white thin layer and color difference.

5. Marking of steel strand

Marking example: structure 1X7, diameter 6.0mm, tensile strength 1370M Pa, Class A zinc layer steel strand marked :1X7-6.0-1370-A-YB/T 5004-2012

Packing, marking and certificate of quality

The packing, marking and quality certificate of steel strand shall be in accordance with GB/T 2104.

In general, all kinds of steel strand wire should be delivered in tray. According to the agreement of both parties, moisture-proof paper, linen, plastic woven cloth and other supplementary packaging can be added.

Post time: Jun-06-2022