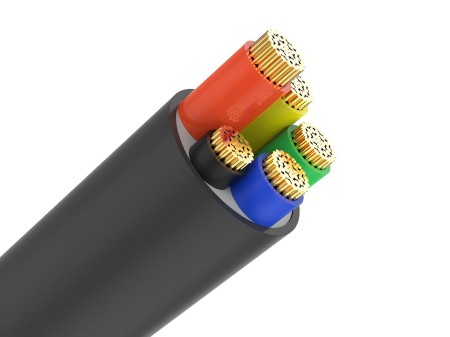

Modern electrical systems rely on interconnections between different devices, circuit boards, and peripherals. Whether transmitting power or electrical signals, cables are the backbone of wired connections, making them an integral part of all systems.

However, the importance of cable jackets (the outer layer that surrounds and protects the inner conductors) is often underestimated. Selecting the right cable jacket material is a critical decision in cable design and manufacturing, especially when used in harsh environments. Understanding the balance between mechanical performance, environmental resistance, flexibility, cost, and regulatory compliance is key to making a wise choice.

At the heart of the cable jacket is a shield that protects and ensures the life and reliability of the inner cable. This protection protects against moisture, chemicals, UV radiation, and physical stresses such as abrasion and impact.

Material for cable jackets ranges from simple plastics to advanced polymers, each with unique properties to meet specific environmental and mechanical requirements. The selection process is critical because the right material ensures optimal performance and protection under the expected use conditions.

There is no “one size fits all” solution for cable jackets. The material selected can vary greatly depending on the unique circumstances of the application.

There are several factors to consider when selecting the right cable jacket material.

1. Environmental Conditions

Chemical resistance is a critical factor in selecting cable jackets, as cables may encounter oils, solvents, acids, or bases, depending on their application. A well-selected cable jacket can prevent degradation or corrosion of its underlying components, thereby maintaining the integrity of the cable over its service life. For example, in industrial environments where chemical exposure is common, it is critical to select materials that can withstand such harsh conditions. Here, the specific chemicals to which the cable will be exposed must be evaluated, as this determines the need for specialized materials such as fluoropolymers to achieve extreme chemical resistance.

Weather and sunlight resistance is another valuable consideration, especially for cables used outdoors. Prolonged exposure to sunlight can weaken traditional materials, leading to brittleness and eventual failure. Materials designed to resist UV radiation ensure that the cable remains functional and durable even in intense sunlight. For such applications, the ideal materials are CPE thermoplastics, CPE thermostats, or EPR thermostats. Other advanced materials, such as cross-linked polyethylene (XLPE), have been developed to provide enhanced UV resistance, ensuring the longevity of the cable in outdoor applications.

Additionally, in environments where the risk of fire is a concern, choosing a cable jacket that is flame retardant or self-extinguishing can be a life-saving choice. These materials are designed to stop the spread of flames, adding an important layer of safety in critical applications. For flame retardancy, excellent choices include PVC thermoplastics and CPE thermoplastics. Such materials can slow the spread of flames while reducing the emission of toxic gases during combustion.

2. Mechanical Properties

The abrasion resistance, impact force, and crushing ability of the cable jacket directly affect the durability of the polyurethane. This is most necessary in applications where the cable traverses challenging terrain or requires frequent handling. In highly mobile applications, such as in robotics or dynamic machinery, choosing a cable jacket with superior mechanical properties can help avoid frequent replacement and maintenance. The best wear-resistant materials for jacket covers include polyurethane thermoplastics and CPE thermoplastics.

3. Temperature Considerations

The operating temperature range of a cable jacket material can be the difference between success or failure for a system. Materials that cannot withstand the operating temperature range of their intended environment may become brittle in cold conditions or degrade when exposed to high temperatures. This degradation can compromise the integrity of the cable and cause electrical insulation failure, resulting in operational disruptions or safety hazards.

While many standard cables may be rated for up to 105°C, specialized PVC applications may need to withstand higher temperatures. For industries such as oil and gas, special applications require materials, such as ITT Cannon’s SJS series materials, which can withstand temperatures up to 200°C. For these high temperatures, a variety of materials may need to be considered, including PVC on the thermoplastic side and CPE or EPR or CPR on the thermostat side. Materials that can operate in such environments can withstand high temperatures and resist thermal aging, ensuring the performance of the cable over time.

Consider high-temperature environments, such as onshore drilling rigs. In these high-pressure, high-temperature environments, it is necessary to select a cable jacket material that can withstand extreme temperatures without degrading or failing. Ultimately, selecting the right cable jacket material can ensure safe and reliable operations while extending the life of the equipment.

4. The Need for Flexibility

Some applications require cables to remain flexible under repeated bending and twisting movements. This need for flexibility does not reduce the need for durability; therefore, materials must be carefully selected to effectively balance these two requirements. In these cases, materials such as thermoplastic elastomers (TPE) or polyurethane (PUR) are favored for their elasticity and resilience.

Cables used in industrial automation, for example, must be highly flexible to accommodate the movement of machinery such as robots. Mesh robots used for tasks such as picking and placing parts are a prime example of this need. Their design allows for a range of motion, placing constant stress on the cables, necessitating the use of materials that can withstand bending and twisting without compromising performance.

After considering environmental conditions, mechanical properties, temperature, and flexibility needs, it is also important to note that the outer diameter of the cable will vary with each material. To remain environmentally friendly, the cable diameter must remain within the sealing confines of the backshell or connector attachment.

Post time: Aug-12-2024