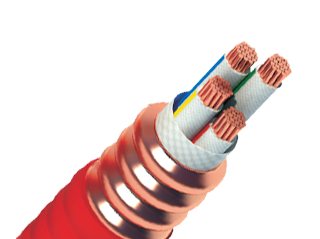

The cable conductor of mineral cables is composed of highly conductive copper, while the insulation layer employs inorganic mineral materials resistant to high temperatures and non-combustible. The isolation layer uses inorganic mineral material, and the outer sheath is made of low-smoke, non-toxic plastic material, exhibiting excellent corrosion resistance. Having gained a basic understanding of mineral cables, would you like to know their key features? Let's delve into that.

01. Fire Resistance:

Mineral cables, being entirely composed of inorganic elements, do not ignite or aid combustion. They do not generate toxic gases even when exposed to external flames, ensuring continued functionality post-fire clearance without the need for replacement. These cables are genuinely fire-resistant, providing an assured guarantee for fire safety circuits, passing the International Electrotechnical Commission's IEC331 test.

02. High Current-Carrying Capacity:

Mineral insulated cables can withstand temperatures up to 250℃ during normal operation. As per IEC60702, the continuous operating temperature for mineral insulated cables is 105℃, considering terminal sealing materials and safety requirements. Despite this, their current-carrying capacity far exceeds that of other cables due to magnesium oxide powder's superior conductivity compared to plastics. Therefore, at the same working temperature, the current-carrying capacity is larger. For lines above 16mm, one cross-section can be reduced, and for areas not permissible for human contact, two cross-sections can be lowered.

03. Waterproof, Explosion-Proof, and Corrosion Resistance:

Utilizing low-smoke, halogen-free, high flame-retardant materials for the sheathing ensures high corrosion resistance (plastic sheathing is only required in cases of specific chemical corrosion). The conductor, insulation, and sheathing form a dense and compact entity, preventing water, moisture, oil, and certain chemicals' intrusion. These cables are suitable for use in explosive environments, various explosion-proof devices, and equipment wiring.

04. Overload Protection:

In plastic cables, overcurrent or overvoltage can cause insulation heating or breakdown during overloads. However, in mineral insulated cables, as long as the heating does not reach the melting point of copper, the cable remains undamaged. Even in instantaneous breakdown, the high temperature of magnesium oxide at the breakdown point does not form carbides. After overload clearance, the cable's performance remains unchanged and can continue to function normally.

05. High Operating Temperatures:

The melting point of magnesium oxide insulation is much higher than that of copper, allowing the cable's maximum normal operating temperature to reach 250℃. It can operate at temperatures close to the melting point of copper (1083℃) for short periods.

06. Strong Shielding Performance:

The copper sheath of the cable serves as an excellent shielding protective layer, preventing both the cable itself from interfering with other cables and external magnetic fields from affecting the cable.

In addition to the aforementioned main features, mineral cables also possess attributes like long lifespan, small outer diameter, lightweight, high radiation resistance, safety, environmental friendliness, mechanical damage resistance, good bending performance, and effective grounding.

Post time: Nov-16-2023