1. Overview Of Marine Cables

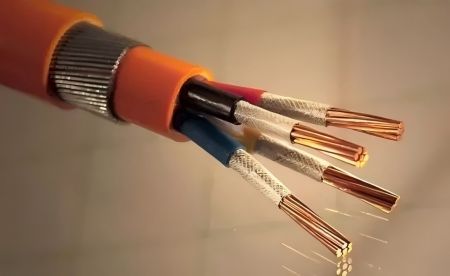

Marine cables are electrical wires and cables used for power, lighting, and control systems in various vessels, offshore oil platforms, and other marine structures. Unlike ordinary cables, marine cables are designed for harsh operating conditions, requiring higher technical and material standards. ONE WORLD, as a professional supplier of cable materials, is committed to providing high-performance and durable raw materials for marine cables, such as high-conductivity copper and high-temperature-resistant insulation materials, ensuring stable performance in demanding environments.

2. Development Of Marine Cables

Cables are electrical components composed of single or multiple conductors and insulation layers, used to connect circuits and electrical appliances. Cables are widely used and come in various types. With the development of the shipbuilding industry, marine cables have evolved into a specialized category, distinct from ordinary cables, and continue to grow. Currently, there are over a dozen types of marine cables with tens of thousands of specifications. As the marine cable industry advances, continuous exploration into quality and technology is ongoing. OW Cable, as a leading supplier of raw materials for wires and cables, focuses on the research and innovation of marine cable materials, such as halogen-free low-smoke materials and cross-linked polyethylene (XLPE) insulation materials, driving technological progress in the cable industry. Marine cables represent the pinnacle of cable technology, ensuring the safety of vessels and playing a critical role in shipbuilding.

3. Classification Of Marine Cables

(1). By Vessel Type: Civilian Cables and Military Cables

① Civilian cables offer a wider variety of types and specifications.

② Military cables require higher safety and reliability. Compared to civilian cables, military cables are crucial for national defense and are legally protected. They prioritize safety, ease of operation, and maintenance over functional diversity, resulting in fewer varieties and specifications.

(2). By General Purpose: Power Cables, Control Cables, and Communication Cables

① Marine power cables are used for power transmission in various vessels and offshore oil platforms. ONE WORLD provides high-conductivity copper and high-temperature-resistant insulation materials, such as cross-linked polyethylene (XLPE) and ethylene propylene rubber (EPR), ensuring efficient power transmission and long service life.

② Marine control cables are used for control signal transmission in vessels and offshore structures.

③ Marine communication cables are used for signal transmission in communication systems, electronic computers, and information processing equipment.

(3). By Insulation Material: Rubber-Insulated Cables, PVC Cables, and XLPE Cables

① Rubber offers excellent elasticity, tensile strength, elongation, wear resistance, tear resistance, and compression set properties, with good electrical insulation. However, it has poor oil resistance, weather resistance, and ozone resistance, as well as low resistance to acid and alkali corrosion. Its heat resistance is limited, making it unsuitable for temperatures above 100°C.

② Polyvinyl chloride (PVC) is widely used but contains halogens. In the event of a fire, PVC cables release toxic gases, causing severe environmental pollution and hindering rescue efforts.

③ Cross-linked polyethylene (XLPE) is the best alternative to PVC, known as a “green” insulation material. It produces no harmful substances when burned, contains no halogen-based flame retardants, and emits no toxic gases during normal operation. OW Cable provides XLPE materials, renowned for their environmental performance and durability, making them the preferred choice for marine cables. Additionally, low-smoke zero-halogen (LSZH) materials are an important option for marine cables.

4. Performance Requirements For Marine Cables

Marine cables must meet the following performance requirements:

Unlike other cables, marine cables require not only basic performance but also excellent electrical, mechanical, aging resistance, moisture resistance, oil resistance, and cold resistance properties. Due to the challenges of installation, higher flexibility is also required.

The selection of materials is driven by the demanding working environment, which requires marine cables to have impact resistance, high wear resistance, corrosion resistance, UV resistance, and ozone resistance. The emission, interference, and performance standards of marine electrical and electronic equipment necessitate electromagnetic compatibility. To ensure the safety of crew members and reduce the risk of fire, marine cables must have high fire resistance ratings. To avoid the release of toxic gases during combustion, marine cables must be halogen-free and low-smoke, preventing secondary disasters. ONE WORLD provides halogen-free low-smoke materials, such as low-smoke zero-halogen polyolefin (LSZH) and mica tape, fully complying with the environmental and safety standards for marine cables.

Different parts of a vessel have varying cable requirements, necessitating the selection of cables with appropriate performance levels based on actual conditions.

5. Market Prospects For Marine Cables

According to recent developments in the domestic and international shipbuilding industry, the future demand for marine cables is expected to focus on large-tonnage vessels with high technological content and added value.

Surveys indicate that the global shipbuilding center is rapidly shifting to China. Currently, the Yangtze River Delta region, leveraging its geographical advantage at the intersection of the golden waterways and coastline, has become a hub for global shipbuilding investment.

While the international market may experience a short-term downturn due to external economic factors, the domestic shipbuilding industry will continue to thrive, driven by China’s marine development strategy. The domestic shipbuilding industry faces vast growth opportunities, with the successful production of an increasing variety of new vessel types. The rapid development of the shipbuilding industry will further boost the demand for marine cables. OW Cable, as a leading brand, will continue to provide high-quality cable materials for the shipbuilding industry, such as high-flexibility drag chain cable materials and oil-resistant, cold-resistant sheathing materials, supporting industry growth.

In addition, vessel maintenance and the construction of related facilities, such as docks, will create significant demand for other types of wires and cables.

6. About ONE WORLD

ONE WORLD specializes in the research and production of marine cable materials, dedicated to providing high-performance and environmentally friendly cable solutions for the global shipbuilding industry. Whether for power cables, control cables, or communication cables, OW Cable offers the highest quality materials and technical support, such as high-conductivity copper, cross-linked polyethylene (XLPE) insulation materials, and low-smoke zero-halogen (LSZH) sheathing materials, ensuring the reliability and safety of cables in harsh environments.

Post time: Mar-17-2025