What is Outdoor Optical Cable?

An outdoor optical cable is a type of optical fiber cable used for communication transmission. It features an additional protective layer known as armor or metal sheathing, which provides physical protection to the optical fibers, making them more durable and capable of operating in harsh environmental conditions.

I. Key Components

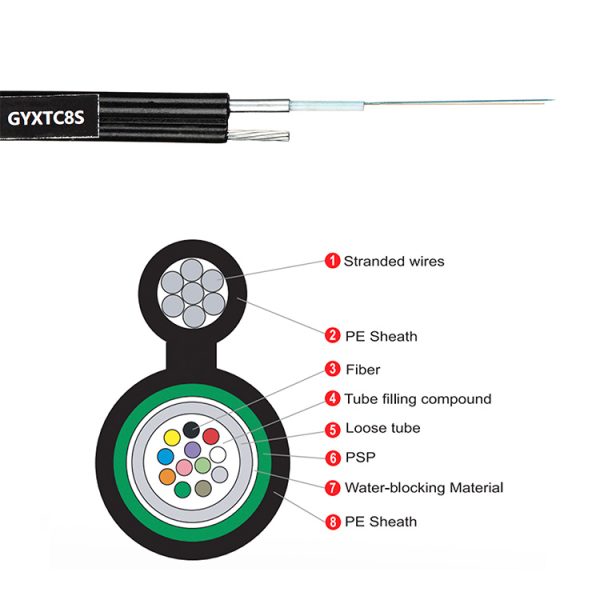

Outdoor optical cables generally consist of bare fibers, loose tube, water-blocking materials, strengthening elements, and outer sheath. They come in various structures such as central tube design, layer stranding, and skeleton structure.

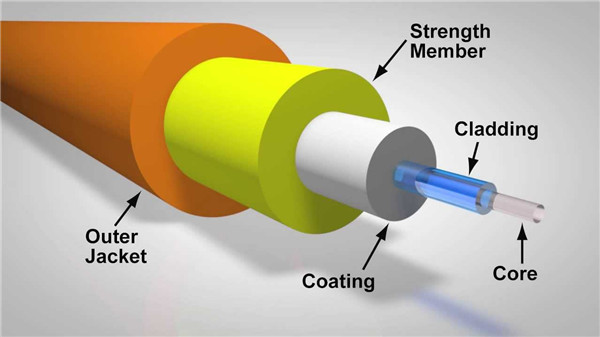

Bare fibers refer to original optical fibers with a diameter of 250 micrometers. They typically include the core layer, cladding layer, and coating layer. Different types of bare fibers have different core layer sizes. For example, single-mode OS2 fibers are generally 9 micrometers, while multimode OM2/OM3/OM4/OM5 fibers are 50 micrometers, and multimode OM1 fibers are 62.5 micrometers. Bare fibers are often color-coded for differentiating between multi-core fibers.

Loose tubes are usually made of high-strength engineering plastic PBT and are used to accommodate the bare fibers. They provide protection and are filled with water-blocking gel to prevent water ingress that could damage the fibers. The gel also acts as a buffer to prevent fiber damage from impacts. The manufacturing process of loose tubes is crucial to ensure the fiber’s excess length.

Water-blocking materials include cable water-blocking grease, water-blocking yarn, or water-blocking powder. To further enhance the cable’s overall water-blocking ability, the mainstream approach is to use water-blocking grease.

Strengthening elements come in metallic and non-metallic types. Metallic ones are often made of phosphated steel wires, aluminum tapes, or steel tapes. Non-metallic elements are primarily made of FRP materials. Regardless of the material used, these elements must provide the necessary mechanical strength to meet standard requirements, including resistance to tension, bending, impact, and twisting.

Outer sheaths should consider the usage environment, including waterproofing, UV resistance, and weather resistance. Therefore, black PE material is commonly used, as its excellent physical and chemical properties ensure suitability for outdoor installation.

II. Features and Applications

Fire Resistance: Due to the presence of a metal sheath, outdoor optical cables demonstrate excellent fire resistance. The metal material can withstand high temperatures and effectively isolate flames, reducing the impact of fires on communication systems.

Long-Distance Transmission: With enhanced physical protection and interference resistance, outdoor optical cables can support longer-distance optical signal transmission. This makes them highly useful in scenarios requiring extensive data transmission.

High Security: Outdoor optical cables can withstand physical attacks and external damage. Hence, they are widely used in environments with high network security requirements, such as military bases and government institutions, to ensure network safety and reliability.

III. Advantages over Regular Optical Cables

Strong Physical Protection: The metal sheath of outdoor optical cables effectively shields the fiber core from external physical damage. It prevents the cable from being crushed, stretched, or cut, providing better durability and stability.

High Interference Resistance: The metal sheath also acts as electromagnetic shielding, preventing external electromagnetic interference from affecting optical signal transmission and enhancing interference resistance.

Adaptation to Harsh Environments: Outdoor optical cables can be used in various harsh environments, including high and low temperatures, humidity, and corrosion. This makes them especially suitable for outdoor cabling, underwater communication, industrial, and military applications.

Additional Mechanical Protection: The metal sheath can withstand significant mechanical pressure and tension, protecting the fibers from external forces and reducing the risk of cable damage.

It’s important to note that outdoor optical cables might incur higher costs and installation complexity compared to regular cables. Due to the presence of the metal sheath, outdoor cables are relatively bulkier and less flexible, making the choice of the appropriate cable type crucial in specific cases.

With its robust physical protection, interference resistance, and adaptability to challenging environments, outdoor optical cables have become the preferred choice for many critical applications, providing essential support for reliable communication transmission.

Post time: Aug-30-2023