Water Blocking Cable Materials

Water blocking materials can generally be divided into two categories: active water blocking and passive water blocking. Active water blocking utilizes the water-absorbing and swelling properties of active materials. When the sheath or joint is damaged, these materials expand upon contact with water, limiting its penetration within the cable. Such materials include water absorbing expanding gel, water blocking tape, water blocking powder, water blocking yarn, and water blocking cord. Passive water blocking, on the other hand, uses hydrophobic materials to block water outside the cable when the sheath is damaged. Examples of passive water blocking materials are petroleum-filled paste, hot melt adhesive, and heat-expanding paste.

I. Passive Water Blocking Materials

The filling of passive water blocking materials, such as petroleum paste, into cables was the primary method for water blocking in early power cables. This method effectively prevents water from entering the cable but has the following drawbacks:

1.It significantly increases the weight of the cable;

2.It causes a reduction in the cable’s conductive performance;

3.Petroleum paste severely contaminates cable joints, making cleaning difficult;

4.The complete filling process is hard to control, and incomplete filling can result in poor water-blocking performance.

II. Active Water Blocking Materials

Currently, the active water blocking materials used in cables are mainly water-blocking tape, water-blocking powder, water-blocking cord, and water-blocking yarn. Compared to petroleum paste, active water blocking materials have the following characteristics: high water absorption and high swelling rate. They can absorb water rapidly and swell quickly to form a gel-like substance that blocks water infiltration, thereby ensuring the insulation safety of the cable. Additionally, active water blocking materials are lightweight, clean, and easy to install and join. However, they also have some drawbacks:

1.Water-blocking powder is difficult to attach evenly;

2.Water-blocking tape or yarn can increase the outer diameter, impairing heat dissipation, accelerating the cable’s thermal aging, and limiting the cable’s transmission capacity;

3.Active water blocking materials are generally more expensive.

Water Blocking Analysis :Currently, the main method in China to prevent water from penetrating the insulation layer of cables is to increase the waterproof layer. However, to achieve comprehensive water blocking in cables, we must not only consider radial water penetration but also effectively prevent the longitudinal diffusion of water once it enters the cable.

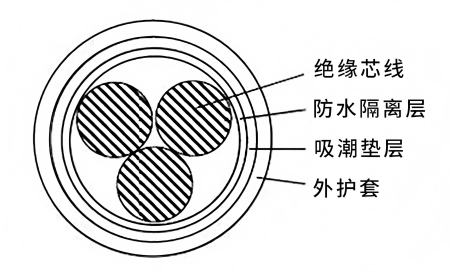

Polyethylene (Inner Sheath) Waterproof Isolation Layer: Extruding a polyethylene water-blocking layer, in combination with a moisture-absorbing cushion layer (such as water-blocking tape), can meet the requirements for longitudinal water blocking and moisture protection in cables installed in moderately damp environments. The polyethylene water-blocking layer is easy to manufacture and doesn’t require additional equipment.

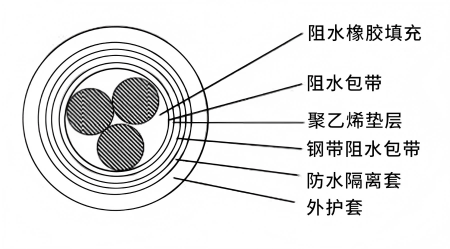

Plastic Coated Aluminum Tape Polyethylene Bonded Waterproof Isolation Layer: If cables are installed in water or extremely damp environments, the radial water-blocking capacity of polyethylene isolation layers may be insufficient. For cables requiring higher radial water-blocking performance, it is now common to wrap a layer of aluminum-plastic composite tape around the cable core. This seal is hundreds or even thousands of times more water-resistant than pure polyethylene. As long as the seam of the composite tape is fully bonded and sealed, water penetration is nearly impossible. The aluminum-plastic composite tape requires a longitudinal wrapping and bonding process, which involves additional investment and equipment modifications.

In engineering practice, achieving longitudinal water blocking is more complex than radial water blocking. Various methods, such as changing the conductor structure to a tight-pressed design, have been used, but the effects have been minimal because there are still gaps in the pressed conductor that allow water to diffuse through capillary action. To achieve true longitudinal water blocking, it is necessary to fill the gaps in the stranded conductor with water-blocking materials. The following two levels of measures and structures can be used to achieve longitudinal water blocking in cables:

1.Use of water-blocking conductors. Add water-blocking cord, water-blocking powder, water-blocking yarn, or wrap water-blocking tape around the tight-pressed conductor.

2.Use of water-blocking cores. During the cable manufacturing process, fill the core with water-blocking yarn, cord, or wrap the core with semi-conductive or insulating water-blocking tape.

Currently, the key challenge in longitudinal water blocking lies in water-blocking conductors—how to fill water-blocking substances between conductors and which water-blocking substances to use remains a focus of research.

Ⅲ. Conclusion

Radial water blocking technology mainly uses water-blocking isolation layers wrapped around the conductor’s insulation layer, with a moisture-absorbing cushion layer added outside. For medium-voltage cables, aluminum-plastic composite tape is commonly used, while high-voltage cables typically use lead, aluminum, or stainless steel metal sealing jackets.

Longitudinal water blocking technology primarily focuses on filling the gaps between the conductive strands with water-blocking materials to block the diffusion of water along the core. From the current technological developments, filling with water-blocking powder is relatively effective for longitudinal water blocking.

Achieving waterproof cables will inevitably affect the cable’s heat dissipation and conductive performance, so it’s essential to select or design the appropriate water-blocking cable structure based on engineering requirements.

Post time: Feb-14-2025