When looking for the best cables and wires, choosing the right sheathing material is crucial. The outer sheath has a variety of functions to ensure the durability, safety and performance of the cable or wire. It is not uncommon to have to decide between polyurethane (PUR) and polyvinyl chloride (PVC). In this article, you will learn about the performance differences between the two materials and the applications for which each material is best suited.

Sheathing structure and function in cables and wires

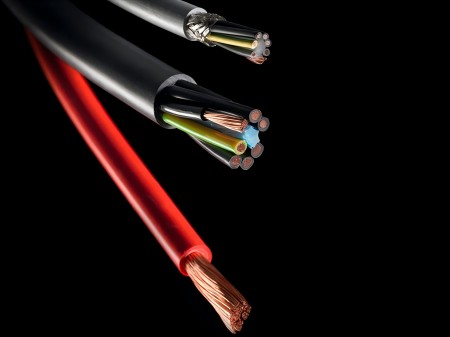

A sheath (also called an outer sheath or sheath) is the outermost layer of a cable or wire and is applied using one of several extrusion methods. The sheath protects the cable conductors and other structural components from external factors such as heat, cold, wet or chemical and mechanical influences. It can also fix the shape and form of the stranded conductor, as well as the shielding layer (if present), thereby minimizing interference with the cable’s electromagnetic compatibility (EMC). This is important to ensure consistent transmission of power, signal, or data within the cable or wire. Sheathing also plays an important role in the durability of cables and wires.

Choosing the right sheathing material is critical to determining the best cable for each application. Therefore, it is important to know exactly what purpose the cable or wire must serve and what requirements it must meet.

The most common sheathing material

Polyurethane (PUR) and polyvinyl chloride (PVC) are the two most commonly used sheathing materials for cables and wires. Visually, there is no difference between these materials, but they exhibit different properties that make them suitable for different applications. In addition, several other materials can be used as sheathing materials, including commercial rubber, thermoplastic elastomers (TPE), and specialty plastic compounds. However, since they are significantly less common than PUR and PVC, we will only compare these two in the future.

PUR – The most important feature

Polyurethane (or PUR) refers to a group of plastics developed in the late 1930s. It is produced by a chemical process called addition polymerization. The raw material is usually petroleum, but plant materials such as potatoes, corn or sugar beets can also be used in its production. Polyurethane is a thermoplastic elastomer. This means that they are flexible when heated, but can return to their original shape when heated.

Polyurethane has particularly good mechanical properties. The material has excellent wear resistance, cutting resistance and tear resistance, and remains highly flexible even at low temperatures. This makes PUR particularly suitable for applications that require dynamic motion and bending requirements, such as towing chains. In robotic applications, cables with PUR sheathing can withstand millions of bending cycles or strong torsional forces without problems. PUR also has strong resistance to oil, solvents and ultraviolet radiation. In addition, depending on the composition of the material, it is halogen-free and flame retardant, which are important criteria for cables that are UL certified and used in the United States. PUR cables are commonly used in machine and factory construction, industrial automation, and the automotive industry.

PVC – the most important feature

Polyvinyl chloride (PVC) is a plastic that has been used to make different products since the 1920s. It is the product of gas chain polymerization of vinyl chloride. In contrast to the elastomer PUR, PVC is a thermoplastic polymer. If the material is deformed under heating, it cannot be restored to its original state.

As a sheathing material, polyvinyl chloride offers a variety of possibilities because it is able to adapt to different needs by changing its composition ratio. Its mechanical load capacity is not as high as PUR, but PVC is also significantly more economical; The average price of polyurethane is four times higher. In addition, PVC is odorless and resistant to water, acid and cleaning agents. It is for this reason that it is often used in the food industry or in humid environments. However, PVC is not halogen-free, which is why it is considered unsuitable for specific indoor applications. In addition, it is not inherently oil resistant, but this property can be achieved by special chemical additives.

Conclusion

Both polyurethane and polyvinyl chloride have their advantages and disadvantages as cable and wire sheathing materials. There is no definitive answer to which material is best for each particular application; Much depends on the individual needs of the application. In some cases, a completely different sheathing material may be a more ideal solution. Therefore, we encourage users to seek advice from experts who are familiar with the positive and negative properties of different materials and can weigh each other.

Post time: Nov-20-2024