In modern industry and daily life, cables are everywhere, ensuring the efficient transmission of information and energy. How much do you know about these “hidden ties”? This article will take you deep into the inner world of cables and explore the mysteries of their structure and materials.

Cable structure composition

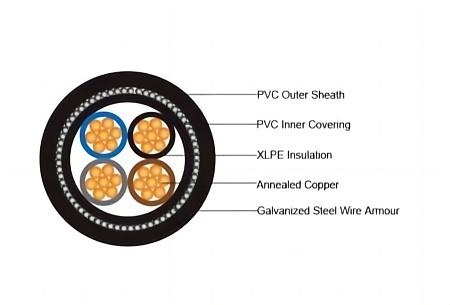

The structural components of wire and cable products can be generally divided into the four main structural components of conductor, insulation, shielding and protective layer, as well as filling elements and bearing elements.

1. Conductor

Conductor is the main component of current or electromagnetic wave information transmission. Conductor materials are generally made of non-ferrous metals with excellent electrical conductivity such as copper and aluminum. The optical cable used in optical communication network uses the optical fiber as the conductor.

2. Insulation layer

The insulation layer covers the periphery of the wire and acts as electrical insulation. Common insulating materials are Polyvinyl chloride (PVC), Cross-linked polyethylene (XLPE), Fluorine plastics, Rubber material, Ethylene propylene rubber material, Silicone rubber insulation material. These materials can meet the needs of wire and cable products for different uses and environmental requirements.

3. Sheath

The protective layer has a protective effect on the insulation layer, waterproof, flame retardant and corrosion resistant. Sheath materials are mainly rubber, plastic, paint, silicone and various fiber products. The metal sheath has the function of mechanical protection and shielding, and is widely used in power cables with poor moisture resistance to prevent moisture and other harmful substances from entering the cable insulation.

4. Shielding layer

Shielding layers isolate electromagnetic fields inside and outside cables to prevent information leakage and interference. The shielding material includes Metallized paper, Semiconductor paper tape, Aluminum foil Mylar tape, Copper foil Mylar tape, Copper tape and Braided copper wire. The shielding layer can be set between the outside of the product and the grouping of each one-line pair or multilog cable to ensure that the information transmitted in the cable product is not leaked and to prevent external electromagnetic wave interference.

5. Filling structure

The filling structure makes the outer diameter of the cable round, the structure is stable, and the inside is strong. Common filling materials include Polypropylene tape, Non-woven PP rope, Hemp rope, etc. The filling structure not only helps to wrap and squeeze the sheath during the manufacturing process, but also guarantees the mechanical properties and durability of the cable in use.

6. Tensile elements

Tensile elements protect the cable from tension, common materials are Steel tape, Steel wire, Stainless steel foil. In fiber optic cables, tensile elements are particularly important to prevent the fiber from being affected by tension and affecting the transmission performance. Such as FRP, Aramid fiber and so on.

Wire and cable materials summary

1. Wire and cable manufacturing industry is a material finishing and assembly industry. Materials account for 60-90% of total manufacturing costs. Material category, variety, high performance requirements, material selection affects product performance and life.

2. The materials used for cable products can be divided into conductive materials, insulating materials, protective materials, shielding materials, filling materials, etc., according to the use parts and functions. Thermoplastic materials such as polyvinyl chloride and polyethylene can be used for insulation or sheathing.

3. The use function, application environment and use conditions of cable products are diverse, and the commonality and characteristics of materials are different. For example, the insulation layer of high-voltage power cables requires high electrical insulation performance, and low-voltage cables require mechanical and weather resistance.

4. Material plays a key role in product performance, and the process conditions and finished product performance of different grades and formulations are very different. Manufacturing enterprises must exercise strict quality control.

By understanding the structural composition and material characteristics of cables, cable products can be better selected and used.

ONE WORLD wire and cable raw material supplier provides the above raw materials with high cost performance. Free samples are provided for customers to test to ensure that the performance can meet customer needs.

Post time: Jun-28-2024