In the structural design of new fire-resistant cables, cross-linked polyethylene (XLPE) insulated cables are widely used. They exhibit excellent electrical performance, mechanical properties, and environmental durability. Characterized by high operating temperatures, large transmission capacities, unrestricted laying, and convenient installation and maintenance, they represent the developmental direction of new cables.

1. Cable Conductor Design

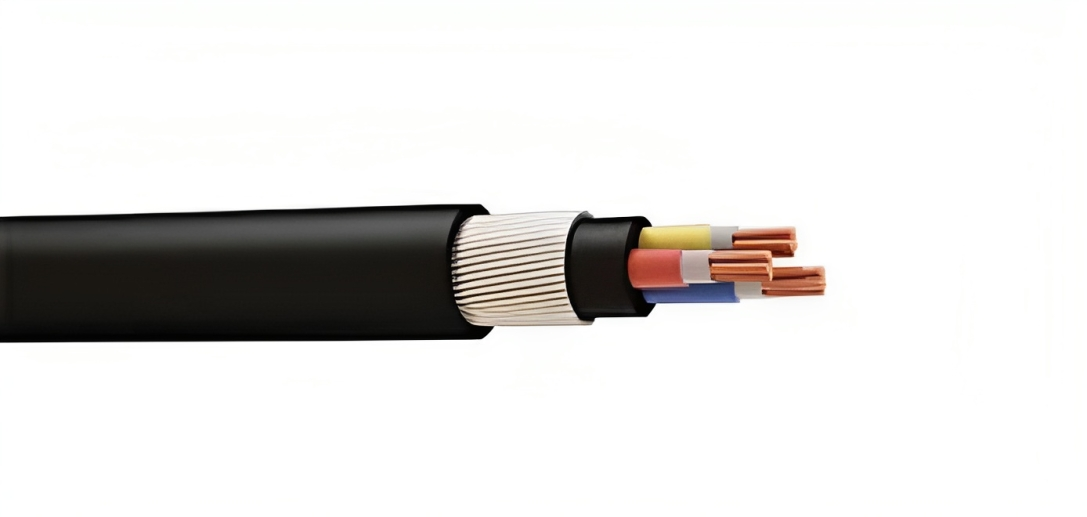

Conductor Structure and Characteristics: The conductor structure adopts a fan-shaped second type of compact conductor structure, using a (1+6+12+18+24) regular stranded structure. In the regular stranding, the central layer consists of one wire, the second layer has six wires, and subsequent adjacent layers differ by six wires. The outermost layer is left-hand stranded, while other adjacent layers are stranded in the opposite direction. The wires are circular and of equal diameter, ensuring stability in this stranding structure. Compact structure: Through compaction, the conductor surface becomes smooth, avoiding concentration of electric fields. Simultaneously, it prevents semi-conductive materials from entering the wire core during extrusion insulation, effectively preventing moisture penetration and ensuring a certain degree of flexibility. Stranded conductors possess good flexibility, reliability, and high strength.

2. Cable Insulation Layer Design

The role of the insulation layer is to ensure the cable's electrical performance and prevent the flow of current along the conductor from leaking outward. An extrusion structure is employed, with XLPE material chosen for insulation. XLPE offers superior performance compared to polyethylene, possessing excellent electrical insulation properties, characterized by minimal dielectric constants (ε) and low dielectric loss tangent (tgδ). It's an ideal high-frequency insulation material. Its volume resistance coefficient and breakdown field strength remain relatively unchanged even after seven days of immersion in water. Hence, it is widely used in cable insulation. However, it has a low melting point. When used in cables, overcurrent or short-circuit faults may cause a rise in temperature, leading to softening and deformation of polyethylene, resulting in insulation damage. To retain the advantages of polyethylene, it undergoes cross-linking, enhancing its heat resistance and resistance to environmental stress cracking, making cross-linked polyethylene material an ideal insulation material.

3. Cable Stranding and Wrapping Design

The purpose of cable stranding and wrapping is to protect the insulation, ensure a stable cable core, and prevent loose insulation and fillers, ensuring the roundness of the core. The flame-retardant wrapping belt provides certain flame-retardant properties.

Materials for Cable Stranding and Wrapping: The wrapping material is a high-flame-retardant non-woven fabric belt, with tensile strength and a flame retardancy index of no less than 55% oxygen index. The filler material uses flame-retardant inorganic paper ropes (mineral ropes), which are soft, with an oxygen index of no less than 30%. Requirements for cable stranding and wrapping include choosing the width of the wrapping band based on the core diameter and the angle of the band, as well as the overlapping or spacing of the wrapping. The wrapping direction is left-handed. High-flame-retardant belts are required for flame-retardant belts. The heat resistance of the filler material should match the cable's operating temperature, and its composition should not adversely interact with the insulation sheath material. It should be removable without damaging the insulation core.

Post time: Dec-12-2023