Wrapping and filling materials

Wrapping refers to the process of wrapping various metal or non-metal materials to the cable core in the form of tape or wire. Wrapping is a widely used process form, and insulation, shielding and protective layer structures are used, including wrapping insulation, wrapping refractory tape, metal shielding, cable forming, armor, braiding and so on.

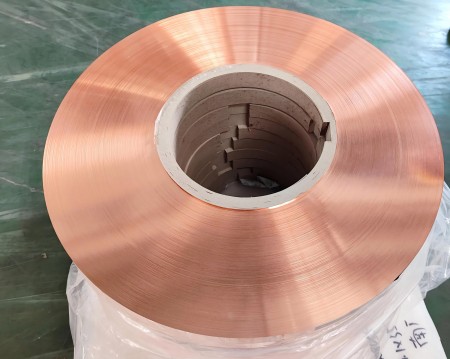

(1) Copper tape, copper-plastic composite tape

Copper tape and copper-plastic composite tape have their respective applications in power cables. Copper tape is mainly used for metal shielding layer, which plays the role of conduction current and electric field shielding, and needs to have high purity, good mechanical properties and appearance quality. Copper-plastic composite tape is based on copper tape, combined with plastic film, used for communication cable shielding, requiring uniform color, smooth surface and no damage, with high tensile strength, elongation and conductivity.

(2) Plastic coated aluminum tape

Plastic coated aluminum tape is the key material for electric power, petroleum, chemical and other fields of cable, because of its excellent waterproof and moisture insulation performance is favored. It is wrapped or longitudinally, and tightly bonded with polyethylene sheath through high pressure and high temperature to form an integrated structure. Plastic coated aluminum tape has standard color, smooth surface, superior mechanical properties, high tensile strength and elongation resistance.

(3) Steel tape, Steel wire

Because of their excellent mechanical strength, steel tape and steel wire are widely used in armor layers and other load-bearing elements in cables that play a mechanical protection role. Steel tape need to be galvanized, tinned or painted to enhance corrosion resistance. The galvanized layer can be passivated in the atmosphere and has high stability, while it can sacrifice itself to protect the steel layer when it encounters water. As armored material, steel wire is indispensable in important occasions such as crossing rivers and oceans, long-span overhead laying. In order to improve the corrosion resistance of the steel wire, the steel wire is often galvanized or coated with high-density polyethylene. Stainless acid-resistant steel wire has higher corrosion resistance and mechanical properties, suitable for special wire and cable.

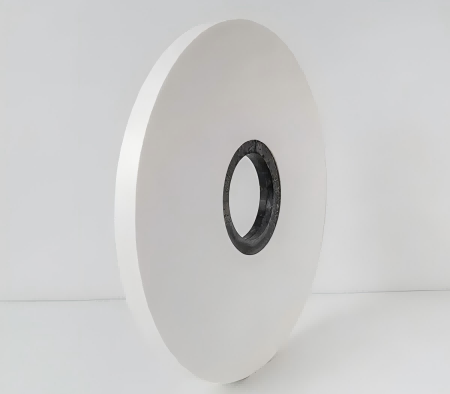

Non-woven fabric tape is also called nonwoven fabric, which is made of synthetic fiber as the main body by adhesive bonding, of which polyester fiber is the most commonly used. Suitable for wrapping or lining of cables. The appearance of fiber distribution is uniform, no mold, hard impurities and holes, no cracks in the width, dry and not wet.

(5) Fireproof tape

Fireproof tape is divided into two categories: fireproof tape and flame retardant, which can maintain electrical insulation under the flame, such as mica tape and ceramic refractory composite tape; Flame-retardant tape, such as glass ribbon, can stop the spread of flame. The refractory mica tape with mica paper as its core has excellent electrical properties and high temperature resistance.

The ceramic refractory composite strip achieves flame retardant effect by firing into ceramic shell insulation layer. Glass fiber tape with its non-combustible, heat resistant, electrical insulation and other characteristics, often used in fire retardant cable reinforcement layer, to provide a strong guarantee for cable safety.

The water blocking tape is composed of two layers of polyester fiber non-woven fabric and highly absorbent material. When water infiltrates, the absorbent material rapidly expands to fill the cable gap, effectively preventing further water intrusion and diffusion. The commonly used highly absorbent materials include carboxymethyl cellulose, etc., which has excellent hydrophilicity and water retention and is suitable for water resistance protection of cables.

(7) Filling material

Cable filling materials are diverse, and the key is to meet the requirements of temperature resistance, non-hygroscopic and no adverse reaction with cable contact materials. Polypropylene rope is widely used because of its stable physical and chemical properties, high mechanical strength and good heat resistance. Prefabricated plastic filler strips are made by recycling waste plastic, which is environmentally friendly and economical. In flame retardant and fire-resistant cables, asbestos rope is widely used for its excellent heat resistance and flame retardant, although its high density increases the cost.

Post time: Oct-28-2024