Products

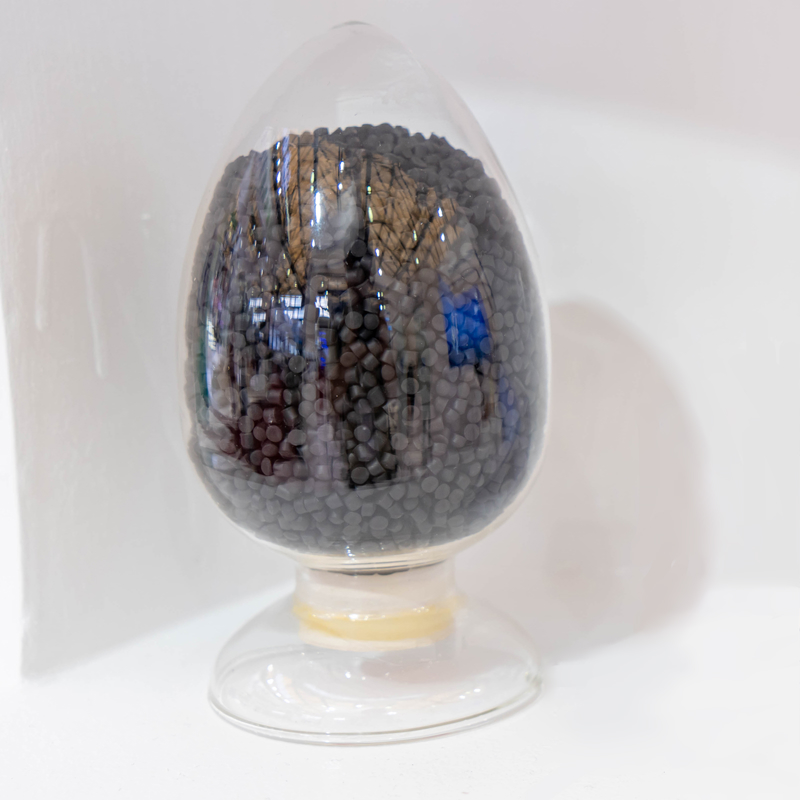

XLPO Compound

XLPO Compound

Product Introduction

This product complies with relevant environmental requirements such as RoHS and REACH. The material performance meets the standards of EN 50618-2014, TUV 2PfG 1169, and IEC 62930-2017. It is suitable for insulation and sheathing layers in the production of solar photovoltaic cables.

| Model | Material A: Material B | Usage |

| OW-XLPO | 90:10 | Used for photovoltaic insulation layer. |

| OW-XLPO-1 | 25:10 | Used for photovoltaic insulation layer. |

| OW-XLPO-2 | 90:10 | Used for photovoltaic insulation or insulation sheathing. |

| OW-XLPO(H) | 90:10 | Used for photovoltaic sheathing layer. |

| OW-XLPO(H)-1 | 90:10 | Used for photovoltaic sheathing layer. |

Processing Indicator

1. Mixing: Before using this product, mix components A and B thoroughly and then add them to the hopper. After opening the material, it is recommended to use it within 2 hours. Do not subject the material to drying treatment. Be vigilant during the mixing process to prevent the introduction of external moisture into components A and B.

2. It is recommended to use a single-threaded screw with equidistant and varying depths.

Compression Ratio: OW-XLPO(H)/OW-XLPO/OW-XLPO-2: 1.5±0.2, OW-XLPO-1: 2.0±0.2

3. Extrusion Temperature:

| Model | Zone one | Zone two | Zone three | Zone four | Machine Neck | Machine Head |

| OW-XLPO/OW-XLPO-2/OW-XLPO(H) | 100±10℃ | 125±10℃ | 135±10℃ | 135±10℃ | 140±10℃ | 140±10℃ |

| OW-XLPO-1 | 120±10℃ | 150±10℃ | 180±10℃ | 180±10℃ | 180±10℃ | 180±10℃ |

4. Wire Laying Speed: Increase the wire laying speed as much as possible without affecting surface smoothness and performance.

5. Cross-Linking Process: After stranding, natural or water bath (steam) cross-linking can be performed. For natural cross-linking, it can be completed within a week at temperatures above 25°C. When using a water bath or steam for cross-linking, to prevent cable adhesion, maintain the water bath (steam) temperature at 60-70°C, and cross-linking can be completed in approximately 4 hours. The above-mentioned cross-linking time is provided as an example for insulation thickness ≤ 1mm. If the thickness exceeds this, the specific cross-linking time should be adjusted based on the product's thickness and cross-linking level to meet the cable's performance requirements. Perform a complete performance test, with a water bath (steam) temperature of 60°C and a boiling time of more than 8 hours to ensure thorough material cross-linking.

Technical Parameters

| No. | Item | Unit | Standard Data | |||||

| OW-XLPO | OW-XLPO-1 | OW-XLPO-2 | OW-XLPO(H) | OW-XLPO(H)-1 | ||||

| 1 | Appearance | —— | Pass | Pass | Pass | Pass | Pass | |

| 2 | Density | g/cm³ | 1.28 | 1.05 | 1.38 | 1.50 | 1.50 | |

| 3 | Tensile Strength | Mpa | 12 | 20 | 13.0 | 12.0 | 12.0 | |

| 4 | Elongation at break | % | 200 | 400 | 300 | 180 | 180 | |

| 5 | Thermal aging performance | Test conditions | —— | 150℃*168h | ||||

| Tensile Strength Retention Rate | % | 115 | 120 | 115 | 120 | 120 | ||

| Retention rate of elongation at break | % | 80 | 85 | 80 | 75 | 75 | ||

| 6 | Short-Term High-Temperature Thermal Aging | Test conditions | 185℃*100h | |||||

| Elongation at break | % | 85 | 75 | 80 | 80 | 80 | ||

| 7 | Low-temperature impact | Test conditions | —— | -40℃ | ||||

| Number of Failures(≤15/30) | 个 | 0 | 0 | 0 | 0 | 0 | ||

| 8 | Oxygen index | % | 28 | / | 30 | 35 | 35 | |

| 9 | 20℃ Volume Resistivity | Ω·m | 3*1015 | 5*1013 | 3*1013 | 3*1012 | 3*1012 | |

| 10 | Dielectric Strength (20°C) | MV/m | 28 | 30 | 28 | 25 | 25 | |

| 11 | Thermal Expansion | Test conditions | —— | 250℃ 0.2MPa 15min | ||||

| Load elongation rate | % | 40 | 40 | 40 | 35 | 35 | ||

| Permanent deformation rate after cooling | % | 0 | +2.5 | 0 | 0 | 0 | ||

| 12 | Burning releases acidic gases | HCI and HBr content | % | 0 | 0 | 0 | 0 | 0 |

| HF content | % | 0 | 0 | 0 | 0 | 0 | ||

| pH value | —— | 5 | 5 | 5.1 | 5 | 5 | ||

| Electrical conductivity | μs/mm | 1 | 1 | 1.2 | 1 | 1 | ||

| 13 | smoke density | Flame Mode | Ds max | / | / | / | 85 | 85 |

| 14 | Original elongation at break test data after pre-treatment at 130°C for 24 hours. | |||||||

| Customization can be done according to the user's personalized requirements. | ||||||||

FREE SAMPLE TERMS

ONE WORLD Is Committed To Providing Customers With Industleading High-Quality Wire And Cable Matenals And First-Classtechnical Services

You Can Request A Free Sample Of The Product You Are Interested Inwhich Means You Are Willing

To Use Our Product For Production

We Only Use The Experimental Data You Are Willing To

Feedback Andshare As The Verification Of Product Characteristics And Quality , Andthen Help

Us To Establish A More Complete Quality Control System Toimprove Customers’ Trust And

Purchase Intention , So Please Restassured

You Can Fill Out The Form On The Right To

Request A Free Sample

Application Instructions

1 . The Customer Has An International Express Delivery Account

Orvoluntarily Pays The Freight ( The Freight Can Be Returned In The Order )

2 . The Same

Institution Can Only Apply For One Free Sample Of Thesame Product , And The Same Institution

Can Apply For Up To Fivesamples Of Different Products For Free Within One Year

3 . The

Sample Is Only For Wire And Cable Factory Customers , And Onlyfor Laboratory Personnel For

Production Testing Or Research

SAMPLE PACKAGING

FREE SAMPLE REQUEST FORM

Please Enter The Required Sample Specifications , Or Briefly Describe Theproject Requirements , We Will Recommend Samples For You

After submitting the form , the information you fill in may be transmitted to the ONE WORLD background for further processed to determine product specification and address information with you. And may also contact you by telephone. Please read our Privacy Policy For more details.