Products

G.652D Optical Fiber

Product Introduction

G.652D optical fiber is ideally designed for use in metropolitan, local and access networks.

G.652D non-dispersion-shifted single-mode optical fiber adopts advanced rod making and wire drawing technology to reduce the water peak loss of 1383nm, and the working wavelength is extended to E-band(1360nm-1460nm), realizing full-band transmission of O, E, S, C and L(1260nm-1625nm). At the same time, it has stable and superior polarization mode dispersion coefficient, which can meet the long distance and high speed transmission.

G.652D non-dispersion-shifted single-mode optical fiber adopts UV curing technology and uses double-layer bending loss-insensitive acrylic resin coating layer, which has a good protective effect on the fiber cladding and can meet the application of different occasions. G.652D optical fiber adopts advanced coating curing technology to provide superior dynamic fatigue resistance and increase the service life of the optical fiber.

characteristics

The G.652D optical fiber we provided has the following characteristics:

1) Achieve O, E, S, C, L(1260nm-1625nm) full-band transmission, increase the transmission bandwidth.

2) Flexible selection of various coatings to meet the needs of different application occasions.

3) Small polarization mode dispersion coefficient, suitable for high-speed transmission.

4) Superior dynamic fatigue resistance, suitable for use in different environments.

Application

Mainly used in various types of optical cable to play the role of communication.

Technical Parameters

Optical Characteristic

| Attenuation | |||||

| Wavelength(nm) | Max.Value(dB/km) bare | Max.Value(dB/km) colored | |||

| 1310 | 0.344 | 0.354 | |||

| 1383 | 0.344 | 0.354 | |||

| 1550 | 0.204 | 0.214 | |||

| 1625 | 0.234 | 0.244 | |||

| Attenuation vs Wavelength | |||||

| Wavelength Range(nm) | Ref. wavelength(nm) | Max. Difference(dB/km) | |||

| 1285~1330 | 1310 | 0.05 | |||

| 1525~1575 | 1550 | 0.05 | |||

| Point Discontinuity | |||||

| Wavelength(nm) | Point Discontinuity (dB) | ||||

| 1310 | 0.05 | ||||

| 1550 | 0.05 | ||||

| Macrobend Loss | |||||

| Mandrel Diameter(mm) | Turn Number | Wavelength(nm) | Induced Attenuation(dB) | ||

| 50 | 100 | 1550 | ≤0.05 | ||

| 50 | 100 | 1625 | ≤0.10 | ||

| Cutoff Wavelength | |||||

| Cable cutoff wavelength(nm) | ≤1260 | ||||

| Mode Field Diameter | |||||

| Wavelength(nm) | Mode Field Diameter(μm) | ||||

| 1310 | 9.2±0.4 | ||||

| Dispersion | |||||

| Wavelength(nm) | Dispersion Value(ps/(nm•km)) | ||||

| 1288~1339 | ≤3.5 | ||||

| 1271~1360 | ≤5.3 | ||||

| 1550 | ≤18 | ||||

| 1625 | ≤22 | ||||

| Zero Dispersion Wavelength(nm) | 1300~1324 | ||||

| Zero Dispersion Slope(ps/(nm2•km)) | ≤0.092 | ||||

| PMD | |||||

| Max. Individual Value (ps/√km) | ≤0.1 | ||||

Dimensional Characteristic

| Fiber Curl(m) | ≥4.0 |

| Cladding Diameter(μm) | 125±1 |

| Core/Cladding Concentricity Error(μm) | ≥0.64 |

| Cladding Non-circularity (%) | ≤1.0 |

| Coating Diameter (uncolored) (μm) | 245±7 |

| Coating Diameter (colored) (μm) | 250±15 |

| Coating Non-circularity (%) | ≤6.0 |

| Coating/cladding Concentricity Error(μm) | ≤12 |

Mechanical Characteristic

| Temperature Dependence (-60℃~+85℃) |

≤0.05dB/km @1310nm &1550nm |

| Damp Heat (85±2℃, Up to 85% RH,30 days) |

≤0.05dB/km @1310nm &1550nm |

| Water Immersion (23±2℃, 30 days) |

≤0.05dB/km @1310nm &1550nm |

| Heat Aging (85±2℃, 30 days) |

≤0.05dB/km @1310nm &1550nm |

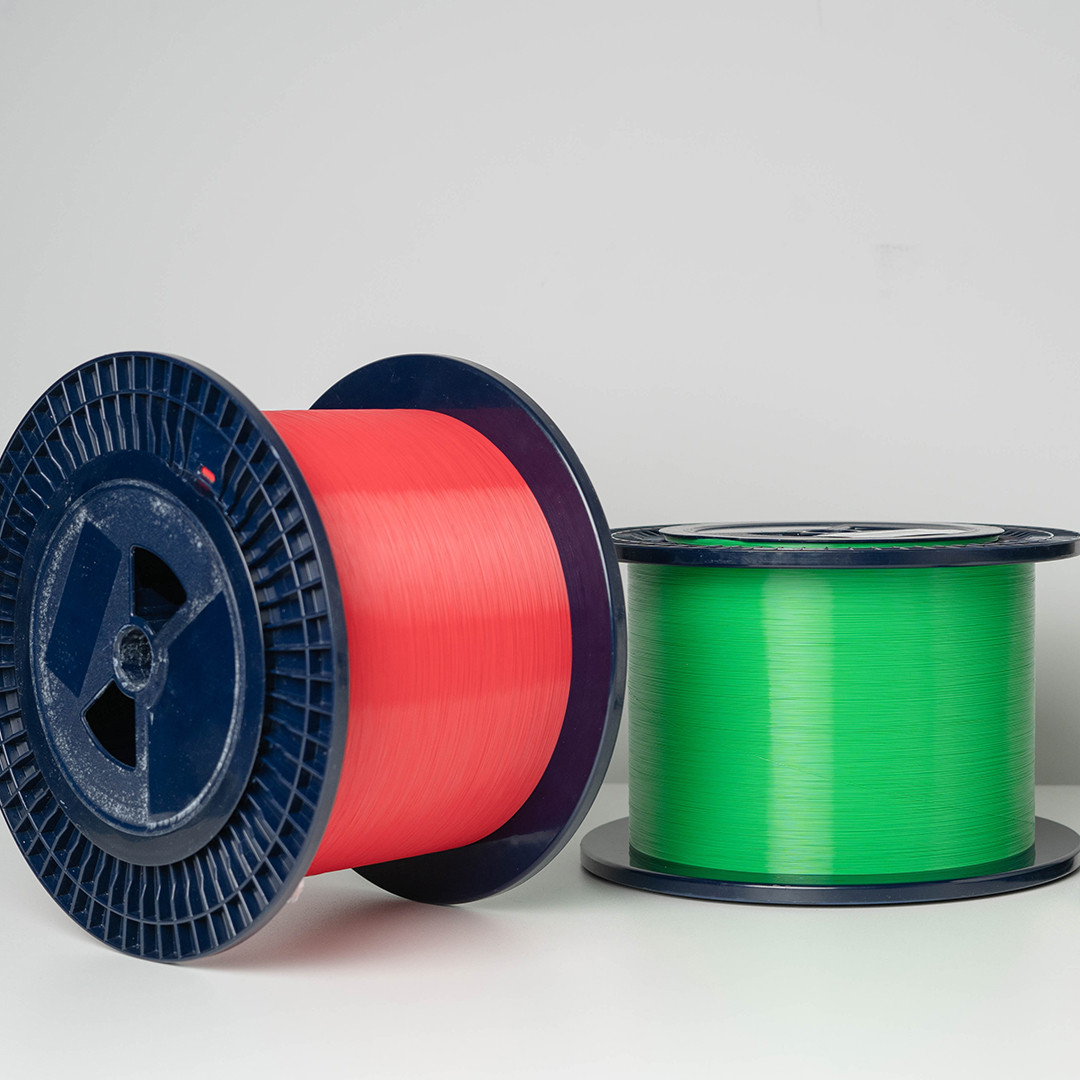

Packaging

G.652D optical fiber is taken up on plastic spool, put into a carton, and then stacked on the pallet and fixed with wrapping film.

Plastic spools are available in three sizes.

1) 25.2km/spool

2) 48.6km/spool

3) 50.4km/spool

Storage

1) The product should be kept in a clean, hygienic, dry and ventilated storehouse.

2) The product should not be stacked together with flammable products and should not be close to fire sources.

3) The product should avoid direct sunlight and rain.

4) The product should be packed completely to avoid moisture and pollution.

5) The product shall be protected from heavy pressure and other mechanical damage during storage.

FREE SAMPLE TERMS

ONE WORLD Is Committed To Providing Customers With Industleading High-Quality Wire And Cable Matenals And First-Classtechnical Services

You Can Request A Free Sample Of The Product You Are Interested Inwhich Means You Are Willing

To Use Our Product For Production

We Only Use The Experimental Data You Are Willing To

Feedback Andshare As The Verification Of Product Characteristics And Quality , Andthen Help

Us To Establish A More Complete Quality Control System Toimprove Customers’ Trust And

Purchase Intention , So Please Restassured

You Can Fill Out The Form On The Right To

Request A Free Sample

Application Instructions

1 . The Customer Has An International Express Delivery Account

Orvoluntarily Pays The Freight ( The Freight Can Be Returned In The Order )

2 . The Same

Institution Can Only Apply For One Free Sample Of Thesame Product , And The Same Institution

Can Apply For Up To Fivesamples Of Different Products For Free Within One Year

3 . The

Sample Is Only For Wire And Cable Factory Customers , And Onlyfor Laboratory Personnel For

Production Testing Or Research

SAMPLE PACKAGING

FREE SAMPLE REQUEST FORM

Please Enter The Required Sample Specifications , Or Briefly Describe Theproject Requirements , We Will Recommend Samples For You

After submitting the form , the information you fill in may be transmitted to the ONE WORLD background for further processed to determine product specification and address information with you. And may also contact you by telephone. Please read our Privacy Policy For more details.